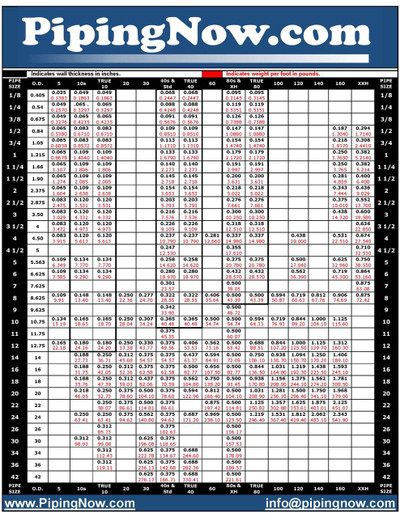

However, we should pay attention to all of these details during design. When the piping size was reduced from 16 NPS to 12 NPS near a block valve it is noticed if the valve is 16 NPS instead of 12. Find out Steel Pipe Dimensions amp Sizes Schedule 40 80. Some of the senseless details are only noticed in the field with the "full-scale" model. All ratings are in psig and are based on ANSI/ASME B 3 1. This normally works well with little real engineering - a sort of 80:20 thing.Įveything looks the same on a P&ID. Ratings are given for standard seamless pipe sizes at temperatures from 100 F to 750 F. The selected piping specification identifies the pipe schedule for each size line as well as some valve specification code, etc. The basis is the fluid composition, pressure, temperature, etc. Within the B31.3 work, process engineers may assign the piping specification from the available contractor or client selection list. Money and safety considerations apply to most projects. (For more specific working pressure information regarding a particular tubing, consult with the actual manufacturer of the tubing. However stainless steel pipe can also be available in other schedules.Ībbreviations used: NPS– Nominal Pipe Size, NB – Nominal bore, STD – Standard, XS – Extra Strong, XXS – Double Extra Strong.Different piping standards would apply to transportation ASME B31.8 gas and B31.4 liquid. System temperatures between -20☏ and 100☏ with allowable stress of 20,000 psi. Stainless steel pipe is most often available in standard weight sizes (noted by the “S” designation, for example “NPS SCH 10S”). The wall thickness associated with a particular schedule depends on the pipe size as can be seen from the charts below for some of the more common sized carbon steel pipes encountered. XXS wall is thicker than SCH 160 from NPS 1/8″ to NPS 6″ inclusive, and SCH 160 is thicker than XXSwall for NPS 8″ and larger. XSis identical to SCH 80 for NPS 1/8 to NPS 8, inclusive. STD is identical to SCH 40 for NPS 1/8 to NPS 10, inclusive. As the schedule number increases, the wall thickness increases, and the actual bore is reduced. wall thickness, affects only the inside diameter. – ASME/ANSI B36.19 Stainless Steel Pipe Does Pipe Schedule Change with Pipe Size?įor all pipe sizes the outside diameter remains relatively constant.

– ASME/ANSI B 36.10 Welded and Seamless Wrought Steel Pipe, and 133' least divider and 450 PSI, while plan 80 has a. To give you a thought of the size contrast, 1' plan 40 PVC pipe has a. This makes it perfect for mechanical and synthetic applications. In the oil and gas and related downstream industries the most common standards are Schedule 80 Pipe Nipple Pressure Rating has thicker dividers and can with stand higher PSI (pounds per square inch). Other than the pipe schedule, pipe thickness can also be specified in mm or inches to the value corresponding to that specified in the ASME standard. For a given size and schedule the thickness of the pipe is fixed and defined in the applicable ASME standard. Wall thickness is expressed in “ schedules“, referred to as pipe schedules. Obviously, for pipes containing pressurised fluids the wall thickness, and by implication the pipe’s strength, is important. This critical dimension is referred to as the nominal bore (NB). As the main function of the pipes is to carry fluid under pressure therefore their internal diameter is their critical dimension.

0 kommentar(er)

0 kommentar(er)